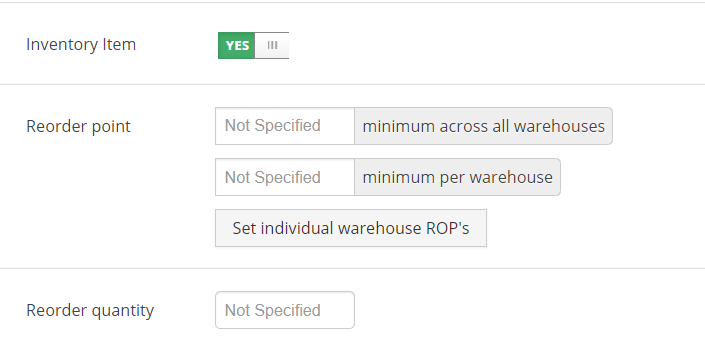

Inventory Items have the ability to have Reorder Points and Reorder Quantities associated with them. Non inventory items do not.

Reorder Points

If an inventory item's stock level falls below the reorder point, the inventory item will be flagged as 'low stock'. A Reorder Point can be defined across potentially 3 different levels. These levels are:

- Minimum across all warehouses

- minimum per warehouse

- set individual warehouse Reorder Point

Different Types of Reorder points:

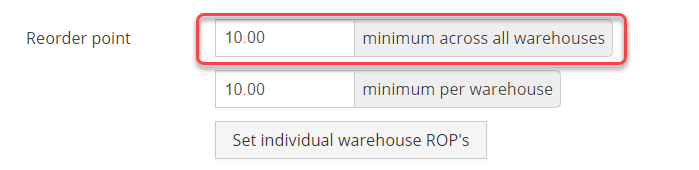

A reorder point set as a minimum across all warehouses -

The number that is entered in this field indicates the quantity that will flag the item as a low stock item when it meets or falls below this number. When the total on hand quantity across all warehouses meets or falls below this number, the inventory item will be flagged as low stock.

For example, if there are 2 warehouses (A and B) and for an inventory item 'Widget A' the reorder point across all warehouses is selected and set to 10, and a quantity of 4 in warehouse A is present and a quantity of 7 in warehouse B is present, this would provide a total of 11 on hand. This would exceed the reorder point selected of 10. Even though the quantity in both warehouses individually is less than 10, when added together, the total quantity on hand across all warehouses exceeds the reorder point, and the item is not flagged as a low stock item.

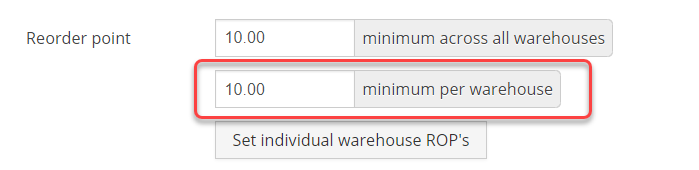

A reorder point set as a minimum per warehouse -

An item will be flagged as low stock when the on hand quantity for the item in any warehouse meets or falls below this number.

Using the example from before, if the reorder point is selected as a minimum of 10 per warehouse, then the inventory item would be flagged as low stock in both warehouse A and warehouse B, assuming the same quantities on hand as the previous example of 4 and 7, respectively.

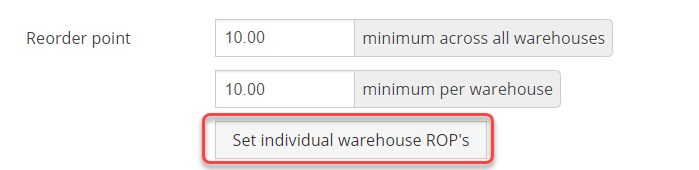

A reorder point set as an individual warehouse ROP -

When this reorder point is selected, Service Fusion will allow a unique reorder point for each warehouse to be entered.

If I need inventory items to be flagged as low stock at different stock levels across the different warehouses, this is the reorder point to use. This reorder point can be assigned per warehouse.

Reorder Quantity

A reorder quantity is the typical quantity that is ordered when the inventory item needs to be ordered. Once an item's stock level falls below the reorder point, it would be flagged as low stock and an order would need to be created. When the order is created, the user creating the order can refer to the item's reorder quantity to know how what quantity of item is typically ordered.